Lock + Load Approved Uses

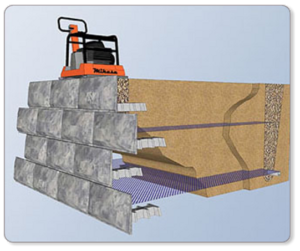

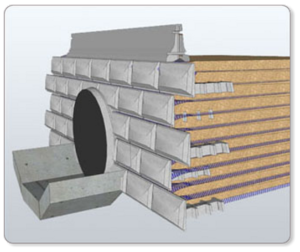

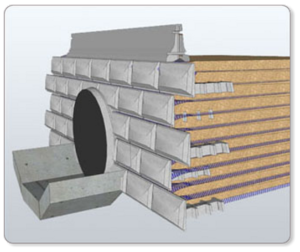

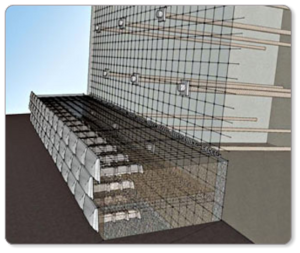

- To date MSE walls are the walls most usually faced with LOCK+LOAD modules.

- MSE Walls may use geogrid, metal mats, or geotextile as the soil reinforcement.

- Crushed rock is compacted in the counterfort zone and drainage placed at the rear of the soil reinforcement to insure a drained condition within the MSE zone.

- Millions of square feet of LOCK+LOAD faced MSE walls have been built and placed into service in the last fifteen years

-

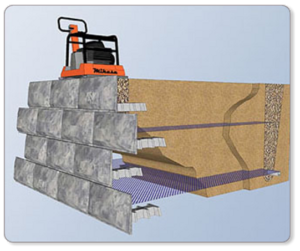

LOCK+LOAD modules may be used as stand alone units to build gravity walls up to a height of four to five feet depending on wall geometry and soil conditions.

-

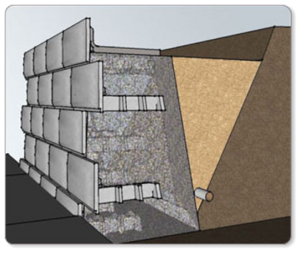

For taller gravity walls a fill zone of approximately one third of the wall height is backfilled, a row at a time, with “No Fines” concrete; a lean mix of cement and 3/4” crushed rock that maintains its permeability while providing the necessary strength to insure a stable retaining structure.

-

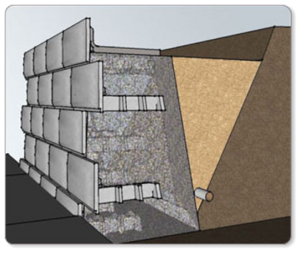

This type of wall is typically used in situations where very high loading is expected and is similar to geogrid / geotextile reinforced MSE walls except that soil reinforcement layers are placed at more frequent intervals (8” or less) to create an extremely strong monolithic block of reinforced fill.

-

Again LOCK+LOAD provides an ideal facing that is easily integrated into the GRS mass

-

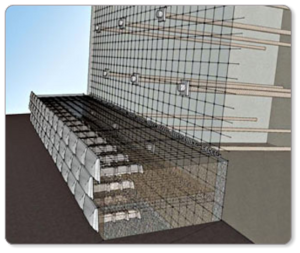

When LOCK+LOAD is used as a fascia for soil nail walls it is used in conjunction with approximately 4 ft. lengths of wire matt soil reinforcement spaced at 32 ‘’ intervals and that are attached to the wall facing mat by way of wire coils.

-

Using soil nail top down construction faced with LOCK+LOAD instead of the more typical shot- crete allows the construction of tall walls in zones where little or or excavation is possible.

-

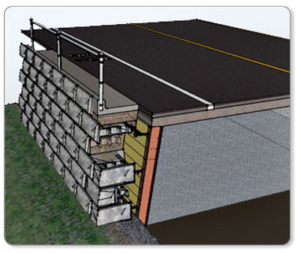

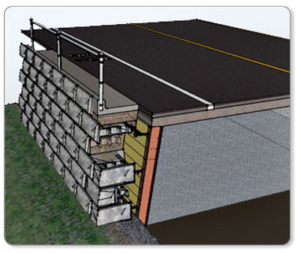

Many projects use H-Pile & lagging as shoring during construction that needs to be faced at the end of the project.

-

LOCK+LOAD can easily be attached to the H-Pile using a “Nelson Stud” and horizontal reinforcing steel cast into a grade beam on top of alternate rows of LOCK+LOAD modules as depicted in the adjacent sketch.